All About Diamond Plated Metal Sheets

Why Diamond Plated Metal Sheets Are Essential for Modern Facilities

Diamond plated metal sheets are textured metal panels featuring a raised diamond pattern that provides excellent slip resistance and durability. These sheets combine safety with industrial aesthetics, making them ideal for high-traffic areas, equipment surfaces, and decorative applications.

Key Benefits of Diamond Plated Metal Sheets:

- Slip Resistance - Raised diamond pattern provides excellent traction even when wet

- Durability - Withstands heavy foot traffic and equipment loads

- Corrosion Resistance - Aluminum and stainless steel options resist rust and degradation

- Versatility - Available in multiple materials, thicknesses, and finishes

- Easy Maintenance - Simple cleaning with mild detergent and water

Diamond plate was originally developed in the 1960s as "tread plate" for vehicle applications where traction was critical. Today, these sheets are widely used in everything from ambulance floors and fire truck steps to walk-in coolers and decorative wall panels.

The manufacturing process involves either hot rolling heated metal through patterned rollers or cold stamping aluminum sheets to create the distinctive raised diamond pattern. Real diamond plate features solid diamonds when viewed from the back, unlike cheaper stamped imitations that are hollow and less durable.

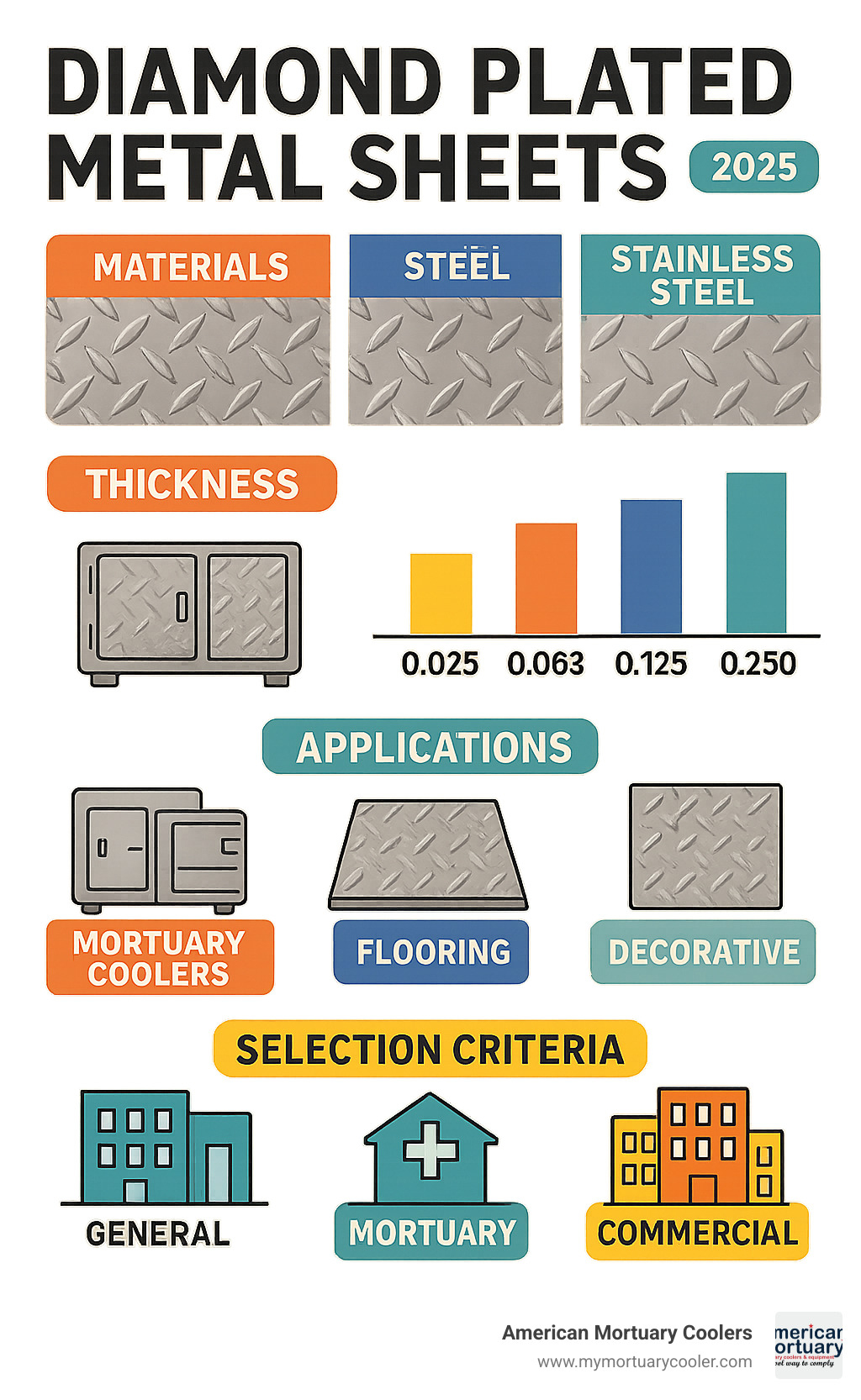

Common materials include aluminum (lightweight and corrosion-resistant), steel (strong and economical), and stainless steel (premium corrosion resistance). Thickness ranges from 0.025" for decorative applications to 0.250" for heavy-duty industrial flooring.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in specifying and installing diamond plated metal sheets for mortuary facilities nationwide. Our expertise in durable, hygienic surfaces helps funeral homes choose the right diamond plated metal sheets for their specific needs and space requirements.

Diamond plated metal sheets word guide:

Understanding Diamond Plate Metal

When you're looking at diamond plated metal sheets, you're seeing the result of impressive manufacturing. There are two main ways these sheets come to life: hot rolling and cold stamping. Steel needs heat treatment, while aluminum is flexible enough to work with at room temperature.

For steel diamond plate, manufacturers heat the metal above its recrystallization temperature, then run it through specially patterned rollers. Aluminum gets the gentler treatment with cold stamping using precision dies - no heat required thanks to aluminum's naturally cooperative nature.

The raised lug geometry isn't just there to look industrial. Those diamond shapes distribute weight loads across the surface while creating air pockets that grab onto shoe soles and equipment. The pattern depth typically runs from 0.014" to 0.025" - deep enough for excellent traction, but not so deep that cleaning becomes difficult.

Diamond plated metal sheets follow strict manufacturing standards like ASTM A786 for steel varieties. Steel diamond plate uses hot-rolled carbon steel for excellent strength at a budget-friendly price. Aluminum 3003-H22 brings that mirror-like shine with exceptional formability. Aluminum 6061-T6 steps up the strength game with superior corrosion resistance for serious industrial applications. Stainless steel T304 is the premium choice, featuring that protective chromium oxide layer that makes it practically bulletproof against corrosion.

Gauge versus thickness works backwards from what you'd expect. Lower gauge numbers actually mean thicker metal. So 14-gauge aluminum measures 0.063" thick, while 8-gauge measures a hefty 0.125" thick.

The corrosion science behind these materials is fascinating. Stainless steel forms a protective chromium oxide layer when it meets oxygen, and this layer actually heals itself when scratched. Aluminum naturally develops its own oxide coating that acts like invisible armor against further corrosion.

Load distribution across the diamond pattern gives these sheets exceptional impact resistance. Each raised diamond acts like a tiny structural beam, spreading point loads across a wider area. Scientific research on slip resistance of textured flooring shows that properly manufactured diamond plate can slash slip incidents by up to 85% compared to smooth surfaces.

Real vs. Fake Diamond Plate

The difference between authentic and imitation diamond plate comes down to what's happening on the back side. Real diamond plate shows solid diamonds when you flip it over - the metal was actually moved and displaced during manufacturing. Fake or stamped versions reveal hollow indentations on the reverse side.

This construction difference is the make-or-break factor for performance. Forged diamond plate keeps its pattern integrity under heavy loads and repeated punishment. Those solid-back diamonds won't collapse or flatten over time because they're built into the metal's structure.

Cosmetic stamped panels work fine for light decorative use - maybe a bar front or accent wall. But ask them to handle real-world flooring or high-traffic applications, and they'll fail quickly.

Stamped panels might cost 30-40% less upfront, but they typically need replacement within 2-3 years in demanding environments. Authentic diamond plate pays for itself through longevity. More info about our services includes detailed comparisons to help you avoid these costly mistakes.

Choosing the Right Diamond Plated Metal Sheets

Selecting the perfect diamond plated metal sheets doesn't have to be overwhelming. Steel offers incredible strength at the lowest cost, making it perfect for indoor applications where moisture isn't a concern. Aluminum strikes a balance between weight and durability - it's about three times lighter than steel while still handling serious abuse. Stainless steel is the premium choice when you need ultimate corrosion resistance.

| Material | Weight (lb/sq ft) | Strength | Corrosion Resistance | Cost | Best Applications |

|---|---|---|---|---|---|

| Steel | 6.16 (.125") | Excellent | Poor (requires coating) | Low | Indoor flooring, ramps |

| Aluminum 3003-H22 | 2.00 (.125") | Good | Excellent | Medium | Decorative, light duty |

| Aluminum 6061-T6 | 2.00 (.125") | Very Good | Excellent | Medium-High | Industrial, outdoor |

| Stainless Steel | 8.00 (.125") | Excellent | Superior | High | Marine, food service |

Stock sizes make ordering straightforward. Most suppliers carry everything from compact 1×1 foot panels up to large 5×12 foot sheets. The 4×8 sheet is the sweet spot for most projects - it's manageable for installation while minimizing seams.

The finish options include gloss black powder coating for a sleek, modern look, race red for high visibility safety areas, and mirror finish stainless steel for premium appearance. Color powder coating and vinyl wrapping open up virtually unlimited customization possibilities.

Edge trim accessories, especially vinyl molding available in 50-foot rolls, make the difference between a DIY look and a professional installation. These protect exposed edges from damage while giving your project that polished appearance.

Sustainability matters more than ever, and metal diamond plate delivers. All three main materials are highly recyclable, with aluminum leading the pack. When ordering, consider bulk pricing. Orders over $500 often qualify for free shipping, and volume discounts can slash costs by 10-15%.

Diamond Plate Sheets 101: Compare Options & Find the Right Fit walks through detailed selection guidance based on your specific facility requirements.

Diamond Plated Metal Sheets Thickness & Weight

The 0.025" cosmetic grade weighs about half a pound per square foot in aluminum. This is your go-to for decorative wall panels and wainscoting where looks matter more than strength. Just don't expect it to handle foot traffic.

The 0.063" light duty thickness steps up to 1.20 pounds per square foot for aluminum. This is the minimum we'd recommend for any area where people will walk. It works well for stair treads, light-duty ramps, and spaces with occasional wheeled equipment.

The 0.125" industrial grade is the workhorse - 2.00 pounds per square foot for aluminum and 6.16 for steel. This thickness handles heavy foot traffic, equipment loads, and frequent cleaning. It's what we typically spec for walk-in coolers, loading docks, and mezzanine flooring where durability can't be compromised.

Deflection limits become important when spanning between supports. A 0.125" aluminum sheet can span 24 inches between supports with minimal flex under normal foot traffic.

Diamond Plated Metal Sheets vs Imitation Panels

Plastic diamond plate panels offer lightweight installation and impressive chemical resistance. They're perfect for temporary applications but lack the durability and professional appearance of metal.

Rubber diamond mats excel at slip resistance and provide cushioning that's great for standing comfort. However, they won't handle wheeled traffic well and can be tricky to sanitize thoroughly.

For mortuary facilities, we typically recommend genuine metal diamond plate. It delivers the hygienic properties, durability, and professional appearance that families expect.

Cutting, Bending & Installing Diamond Plate

Fabricating diamond plated metal sheets requires the right tools and techniques for professional results. For cutting, a circular saw with a fine-tooth sheet metal blade (24-32 TPI) provides clean, straight cuts. A jigsaw works well for curves and cutouts, while aviation snips handle light-gauge material.

For high-volume or precision work, consider professional cutting services. Water-jet cutting provides the cleanest edges, while plasma cutting offers speed for thicker materials.

When preparing for welding, the diamond pattern creates challenges. Countersinking the diamonds in the weld area provides better electrode access and stronger joints. How to Weld Diamond Plate in 5 Simple Steps covers proper techniques for achieving strong, clean welds.

Fastening options depend on the substrate and application:

- Self-tapping screws: Best for steel framing, use stainless steel screws to prevent galvanic corrosion with aluminum

- PL Premium adhesive: Construction adhesive works well for wall panels, providing strong bonds without visible fasteners

- Expansion gaps: Allow 1/8" per 10 feet for thermal expansion, especially important for large outdoor installations

- Indoor/outdoor fasteners: Use appropriate materials - stainless steel for marine environments, galvanized for standard outdoor use

Custom edge molding provides professional finishing touches. Vinyl edge trim snaps over sheet edges, covering sharp corners and providing a finished appearance.

Safety equipment is non-negotiable when working with metal sheets. Safety glasses, work gloves, and hearing protection are minimum requirements.

DIY Friendly Techniques

For thin materials (0.025"), score-and-snap techniques work well for straight cuts. Score the back side with a utility knife, then bend sharply to break along the line.

A bending brake allows precise bends for custom applications. Most diamond plate bends easily along the diamond pattern but requires more force across the pattern.

Rivet spacing for mechanical fastening should follow the 3-5 rule: minimum 3 rivet diameters between rivets, maximum 5 diameters for structural applications.

Hidden fastener systems create clean appearances for wall installations. Z-clips or French cleat systems allow panels to be removed for maintenance while maintaining a seamless look.

Tiling multiple panels can reduce freight costs significantly. A 2×4 configuration of 2×2 panels ships more economically than a single 4×8 sheet due to freight class differences.

Applications, Accessories & Creative Ideas

Diamond plated metal sheets have found their way into nearly every industry. What started as simple truck bed liner has evolved into a versatile material that solves problems from factory floors to fancy restaurant bars.

In our mortuary facilities, we see diamond plate shine in walk-in coolers where staff need secure footing on potentially wet surfaces. The raised pattern provides excellent traction while being easy to sanitize. More info about flexible pickup bed solutions shows how this same durability translates to vehicle applications.

Transportation applications remain hugely popular. Truck beds lined with diamond plate handle years of abuse from tools, equipment, and cargo. Industrial settings rely heavily on diamond plate for stair treads and mezzanine flooring. Safety managers love that the slip-resistant surface often meets OSHA requirements while lasting decades with minimal maintenance.

The decorative possibilities might surprise you. Modern restaurants use diamond plate for bar fronts and wainscoting to create that industrial-chic look. Food trucks practically live on diamond plate - it handles spills, looks professional, and stands up to constant cleaning. Fitness centers use it for weight room flooring where dropped weights would destroy other materials.

Marine applications showcase diamond plate's corrosion resistance. Boat decks need materials that won't rust in saltwater while providing sure footing on wet surfaces. Aluminum and stainless steel diamond plate handle these harsh conditions beautifully.

We've even seen creative uses in custom furniture and architectural features. The way light plays across the diamond pattern creates interesting visual effects that designers love.

Finishing Touches & Trim Options

The difference between a professional installation and a DIY disaster often comes down to the finishing details. Raw diamond plate edges are sharp and look unfinished.

Vinyl edge trim transforms these installations. Available in 50-foot rolls, this trim fits sheets up to 0.063" thick and includes an internal adhesive bead that creates a permanent bond. The trim protects people from sharp edges while giving your installation that finished, professional look.

Inside and outside corner pieces solve the puzzle of where panels meet at angles. J-caps handle the tricky spots where diamond plate meets other materials like drywall or concrete.

Quality sealants matter too. Polyurethane-based caulks stay flexible as materials expand and contract, preventing water infiltration. We avoid silicone sealants in high-traffic areas because they tend to collect dirt.

Color-matched screws and fasteners complete the professional appearance. Stainless steel fasteners prevent those ugly rust stains that develop over time, especially in humid environments like coolers.

These finishing touches might add 15-20% to your material costs, but they're what separate installations that look great for decades from those that start looking shabby within months.

Maintenance, Outdoor Durability & Buying Tips

Taking care of your diamond plated metal sheets isn't rocket science, but doing it right makes all the difference in how long they'll look great and perform well.

For everyday cleaning, you can't go wrong with mild detergent and warm water. Grab a soft-bristle brush and work with the diamond pattern - those raised diamonds actually help break up dirt and grime.

Avoid abrasive cleaners or steel wool at all costs. They might seem like they'll cut through tough stains faster, but they'll scratch the surface and create spots where corrosion can start.

For stubborn stains, specialized aluminum or stainless steel cleaners work wonders. Just test any new cleaner in a corner first. Polishing compounds can bring back that showroom shine to aluminum surfaces, but use them sparingly.

If you're dealing with harsh environments - salt air, industrial chemicals, or extreme weather - sealing wax adds an extra layer of protection. Marine-grade waxes handle saltwater exposure like champs.

Regular corrosion checks are especially important for steel diamond plate. Catch surface rust early and you can remove it with naval jelly or phosphoric acid-based rust removers, then touch up with paint.

Many folks actually prefer the natural patina that develops on aluminum over time. This oxidation actually improves corrosion resistance and creates an attractive matte finish.

UV stability varies depending on what you choose. Bare aluminum and stainless steel will look the same in 20 years. Painted finishes might fade over time, with darker colors generally holding up better.

Salt-spray environments are where material choice really matters. Stainless steel is your best friend here, with aluminum alloys coming in second. Steel diamond plate needs protective coatings and regular maintenance near the ocean.

When crunching numbers, don't forget about life-cycle costs. That stainless steel installation might cost 50% more upfront, but if it lasts 3-4 times longer than steel, you're actually saving money in the long run.

Order swatches first - this saves tons of headaches later. Many suppliers offer free sample programs. Regional suppliers often beat distant ones on both freight rates and delivery times. Understanding freight class (typically 85-100 for diamond plate) helps you budget shipping costs accurately.

At American Mortuary Coolers, we've learned that getting samples upfront and working with reliable suppliers makes all the difference. Get $5 off when you sign up for updates on new products and maintenance tips.

Frequently Asked Questions about Diamond Plate

How is diamond plate manufactured?

The manufacturing process for diamond plated metal sheets varies depending on the material. For steel diamond plate, flat metal sheets are heated to 1000-1200°F to make the metal malleable. These heated sheets then pass through specialized embossing rollers that have the diamond pattern precisely machined into their surface.

As the hot steel moves through these rollers, it flows into the diamond-shaped cavities, creating those distinctive raised diamonds. Aluminum takes a different path using cold stamping at room temperature, using powerful dies to force the aluminum into the diamond pattern.

Authentic diamond plate actually displaces metal during manufacturing, creating solid diamonds all the way through. When you flip a real piece over, you'll see solid bumps on the back. Cheaper imitation versions just press shallow indentations into the surface, leaving hollow backs that will fail under real-world conditions.

Can diamond plate be used outdoors year-round?

Absolutely, but choosing the right material makes all the difference. Aluminum diamond plate is your outdoor champion - it won't rust, rot, or corrode no matter what Mother Nature throws at it. The aluminum naturally forms a protective oxide coating that actually heals itself when scratched.

Stainless steel takes outdoor durability even further. Its chromium oxide layer provides bulletproof protection against corrosion, even in brutal saltwater environments. If you're near the ocean or dealing with road salt, marine-grade stainless steel (316L) laughs at conditions that would destroy other materials.

Steel diamond plate is the budget option, but it needs help to survive outdoors. Hot-dip galvanizing gives it excellent protection, while painted finishes require regular touch-ups.

What thickness should I pick for flooring vs décor?

For decorative applications, the ultra-thin 0.025" to 0.032" range works beautifully for wall panels and wainscoting where looks matter more than strength. This thickness cuts easily and keeps costs reasonable, but don't expect it to handle foot traffic.

When people will be walking on your diamond plated metal sheets, 0.063" becomes your minimum thickness. This works great for stair treads, light-duty ramps, and areas with occasional foot traffic.

For serious flooring applications, 0.125" to 0.250" thickness is non-negotiable. This range handles everything from heavy equipment to constant foot traffic without breaking a sweat.

In our mortuary cooler installations, we typically spec 0.125" minimum for floor surfaces and 0.063" for wall applications. This combination provides the durability funeral homes need while keeping the project economical.

Conclusion

Choosing the right diamond plated metal sheets isn't just about picking a surface material - it's about investing in safety, durability, and the professional image that families expect when they trust you with their loved ones. After decades of helping funeral homes across the country, we've seen how the right materials make all the difference in creating facilities that serve families with dignity and respect.

At American Mortuary Coolers, we've learned that every facility has unique needs. Our custom solutions advantage means you get exactly what your specific situation demands, not a one-size-fits-all approach that might work "well enough."

The beauty of diamond plated metal sheets lies in their versatility. Whether you need slip-resistant flooring for your prep areas, hygienic wall panels for walk-in coolers, or durable surfaces that can handle the daily demands of funeral service operations, these materials deliver performance you can count on year after year.

Our nationwide delivery network ensures that whether you're in rural Georgia or downtown Chicago, you'll receive the same quality materials and expert guidance. We understand that funeral service doesn't wait for convenient delivery schedules, which is why our logistics team works around your needs.

The durability assurance that comes with properly specified diamond plate aligns perfectly with our commitment to funeral service professionals. When a family is going through their most difficult time, the last thing you need to worry about is whether your equipment and surfaces will perform reliably. Quality materials installed correctly become invisible - they simply work, day after day, allowing you to focus on what matters most.

For guidance custom to your specific facility needs, we invite you to request a quote from our team. Our specialists combine technical knowledge with real-world funeral service experience, helping you make decisions that serve your facility well for decades to come.

A Practical Guide to Choosing Diamond Stainless Steel Products offers additional insights for premium installations, while our complete collection of coolers and sheet materials ensures you'll find exactly what your facility requires.

Ready to explore how diamond plated metal sheets can improve your facility's safety, durability, and professional appearance? Contact us today to discuss your specific requirements. Our nationwide network of specialists understands the funeral industry's unique demands and is ready to help you create solutions that honor the families you serve.